Hydrogen Peroxide Analyser – PeroxiSense

Hydrogen Peroxide Analyser

Online, continuous Hydrogen Peroxide Analysers, Hydrogen Peroxide Monitors, Hydrogen Peroxide Meters and Hydrogen Peroxide Controllers make up the PeroxiSense range which utilises the very latest and best hydrogen peroxide sensors available in the world today. It is a membraned device which uses no reagents, is extremely stable, and has reduced maintenance and reduced whole life costs.

Flexible & Affordable Hydrogen Peroxide Sensors

The PeroxiSense hydrogen peroxide sensors, which give a hydrogen peroxide measurement in ppm or mg/l, and a range of flow cells, are available with different hydrogen peroxide controllers giving you the same great performance with different communication, display and control options. With the PeroxiSense range of hydrogen peroxide analysers, you get everything that you need – and nothing that you don’t.

The PeroxiSense Hydrogen Peroxide Monitor is used in many applications requiring the measurement of hydrogen peroxide concentration simply for hydrogen peroxide monitoring or hydrogen peroxide dosing control.

The membraned amperometric hydrogen peroxide sensor is a two electrode sensor which operates at an elevated applied potential which in turn eliminates zero drift. Its unique design means that no reagents or buffers are required at all and calibration is a simple one point (no zero required) operation. In addition to the state of the art amperometric hydrogen peroxide sensor, the PeroxiSense range of controllers has all the functionality that you need. Choose from the CRONOS® or CRIUS®4.0 controller to give you the highest quality hydrogen peroxide monitor, with all the functionality you need, at the lowest price possible. This means that you pay for everything you need, and nothing you don’t, without sacrificing the quality of measurement.

Pi’s hydrogen peroxide analyser is designed to have reduced maintenance, reduced calibration and reduced spares requirements. The PeroxiSense H2O2 analysers are undeniably the most cost effective H2O2 analysers available. In most situations the PeroxiSense analyser is able to control the dosing of H2O2 by adjusting flow rates, pump rates, or valve positions automatically to maintain the hydrogen peroxide set-point. Automatic dosing can significantly reduce reagent costs, and increase the level of control.

- Amperometric sensors – continuous online hydrogen peroxide ppm measurement

- No chemical reagents – lower cost of ownership

- Stable and reliable – excellent process control

- Suitable for all potable and process waters

- Up to 6 months between maintenance

- Multiple sensors – reduced cost

- Additional sensors of different types including pH, ORP and conductivity are available

The PeroxiSense hydrogen peroxide measurement sensors and flow cells are available with different controllers giving you the same great performance with different communication, display, and hydrogen peroxide dosing control options.

See The Hydrogen Peroxide Controller In Action

- Hydrogen Peroxide Dosing Control

- Bottle Washers

- Rinsers

- Sea Water

- CIP Plants

- Drinking Water

Anywhere you have a requirement to measure residual H2O2 is a suitable application for PeroxiSense. The PeroxiSense hydrogen peroxide monitor range is particularly suited to working in sites where reliability and ease of use are most important.

Why not click here and ask for a demonstration of all that our hydrogen peroxide analysers can do for you?

Pi’s PeroxiSense hydrogen peroxide sensors and flow cells are available with different controllers giving you the same great performance with different communication, display, and control options.

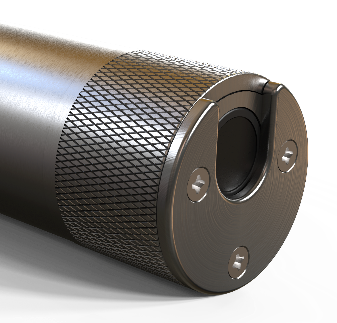

The PeroxiSense hydrogen peroxide analyser can be installed in a variety of auxiliary flow cells and self-cleaning devices.

The PeroxiSense sensors can come equipped to automatically clean themselves at user defined intervals, with all the benefits of no operator intervention for up to 6 months. The AutoFlush is particularly useful in food preparation, pulp and paper, and many applications where there is likely to be a build up of solids in the sample. For more information about AutoFlush click here.

The whole range of PeroxiSense Hydrogen Peroxide Monitors and Controllers can be fitted with additional sensors such as ORP or pH. Please ask your local distributor for more details.

The CRONOS® and CRIUS®4.0 controllers can be equipped with data-logging, relay outputs, analogue outputs and serial communications such as: Ethernet, Modbus and Profibus. Remote monitoring of the instruments (including remote access to all control options) is available via the internet over GPRS and via a LAN. In fact the CRIUS®4.0 PeroxiSense monitor has all the options you could want, whilst the CRONOS® provides a low cost alternative and is particularly great value for money!

Focus Ons are a series of short articles distributed by email providing technical information regarding instrumentation, process measurement in potable, waste, process and pool waters. If you would like to join the mailing list, please contact us.

Membraned sensors come with many advantages over non-membraned sensors such as higher resolutions, fewer interferents and a greatly reduced effect of flow rate changes. These advantages can make a huge difference to the bottom line, particularly if the cost of the chemical being dosed is quite high. For free chlorine sensors, using a membrane can make your measurement much less dependent on pH (if you are using sensors from Pi), meaning your measurement is a more accurate reflection of chlorine residual.

As such, membraned sensors are now largely the norm in residual chlorine measurement and are also prevalent for chlorine dioxide and ozone monitors, but did you know that…

…membraned sensors are sensitive to changes in pressure?

…flow cell outlets can airlock even when water is flowing through them?

…membraned sensors can still be used when the outlet does not go to drain?

…Pi has engineered and designed solutions to all of these potential issues?

Sensitivity to pressure

Membraned sensors do have one property that needs to be carefully managed; they are sensitive to pressure. Pi was an early adopter of membrane technology, so we know that the installation of these sensors is just as important as the sensor itself. In fact, the same sensors in different flow cells can give very different results.

In order to prevent pressure variations affecting the probe, Pi typically uses open flow cells which eliminate variability in pressure before it reaches the probe.

Flow

Whether the sample to the cell is pumped, gravity fed, or comes from a pressurised line, it is important that the flow is controlled to within a range of 350-1000ml per minute, to ensure that sufficient flow is reaching the sensor and to prevent the flow cell overflowing.

If the flow to the cell is variable, Pi can provide a dole valve which controls the flow to approximately 500ml per minute, which prevents the cell from overflowing when pressure variations mean more flow than the cell can handle, while also ensuring adequate flow when the sample line flow/pressure reduces.

Airlocks

The outlet of the flow cell needs to be open to atmosphere, and completely unobstructed. Any system with a long outlet line (particularly flexible pipe) is prone to get airlocks, which will cause the cell to overflow. Outlets which are visually clear and even have water flowing through them, can be partially airlocked which causes backpressure to overflow the cell. This is very easy to diagnose as if you see the cell overflowing and remove the outlet pipe, you will see the cell go back to normal operations within approximately 10 seconds. If this is a persistent problem, consider putting in an air break using a commercially available tundish.

Outlets that do not go to drain

The water from a membraned sensor doesn’t have to go to drain. For processes where saving water is a high priority, a simple tank and pump system that will pump sample water back into your main process line will allow water losses to be reduced to almost zero. Pi’s CRIUS®4.0 controller can be used to control this return process and ensure that this tank never overflows and can automatically drain itself periodically to avoid sediment build up.

What if things go wrong?

As any water engineer can tell you, no matter how well the system is designed, lines can clog, pumps can break and someone on site could fiddle with the settings. Pi recognises these challenges and has engineered solutions into our systems. All Pi membraned sensors have the option to be able to:

- Have a flow switch to detect sample flow loss.

- Use dosing overfeed protection to protect against clogged dosing lines or pump failure.

- Have remote access for SMS or email alarms.

- Use relays to trigger beacons or sirens for alarms or control valves and pumps.

- Customise user security levels to control who can change what settings.

- Use status logs that show what happened to the system and when.

Closed Flow Cells

For membraned sensors, the best way of housing a membraned sensor is with an open flow cell. There are some occasions where this solution just isn’t practicable and in those instances the closed flow cells from Pi, which can take an overpressure of up to 3 bar, are the best solution.

Many different sites ranging across the whole water industry have a daily struggle to keep instrumentation functioning correctly due to fouling. However, did you know that…

…self cleaning and self flushing systems are now available from Process Instruments for most types of sensors?

…these fouling removal systems can extend the life of sensors and drastically reduce maintenance regimes?

…Pi’s self cleaning/flushing systems are affordable, simple and trouble free by design?

Sensor Fouling

Whatever the process being monitored is, there is often something in the sample water capable of fouling a sensor, and therefore causing erroneous results. The obvious solution to this problem is to clean the sensor, but how regular should inspection and cleaning programs be for each piece of instrumentation? Too regular and the inspection and cleaning regime is time consuming and unnecessarily costly. Not often enough and the instrumentation will give false results and probably fail prematurely.

Whatever the process being monitored is, there is often something in the sample water capable of fouling a sensor, and therefore causing erroneous results. The obvious solution to this problem is to clean the sensor, but how regular should inspection and cleaning programs be for each piece of instrumentation? Too regular and the inspection and cleaning regime is time consuming and unnecessarily costly. Not often enough and the instrumentation will give false results and probably fail prematurely.

What is the solution?

Process Instruments’ AutoClean and AutoFlush Systems

Simple, reliable and easy to maintain, Process Instruments’ AutoClean/AutoFlush systems are an alternative to mechanical cleaning mechanisms which can clog and break. By regularly spraying the sensor/probe with clean water or air, the sensor remains clean and free from fouling for extended periods of time. The sensor cleaning cycle is activated by Pi’s controller for a user selectable length of time and frequency so that no matter how dirty the application, the probe remains clean. With no moving parts in the sensor body or in the cleaning attachment there is nothing to replace or check other than a simple valve positioned in an easy to reach location. Pi’s AutoClean and AutoFlush systems can give trouble free and fouling free functioning of sensors for weeks, if not months, at a time.

Pi’s AutoClean and AutoFlush systems can give trouble free and fouling free functioning of sensors for weeks, if not months, at a time.

A solution for each application

AutoClean

This option can be added to our pH, ORP, Turbidity, Suspended Solids and Dissolved Oxygen (DO) sensors. Consisting of an end cap to direct the flow of clean water (or air for a DO sensor) across the face of the sensor blasting any dirt away. The cleaning is controlled by a single valve positioned in an easily accessible location.

AutoVerify

If using air to clean a DO sensor the system can also automatically verify that the sensor is still responding correctly, removing any need to remove the sensor from the sample for months at a time.

If using air to clean a DO sensor the system can also automatically verify that the sensor is still responding correctly, removing any need to remove the sensor from the sample for months at a time.

AutoFlush

For sensors that require flow cell mounting like Chlorine, Ozone and Chlorine Dioxide, an AutoFlush system has inbuilt valves which automatically start/stop the sample flow and control the flow of clean water past the probe. The user can set the flushing interval and duration to keep the flow cell and sensor clear from fouling. For particularly dirty or stubborn contaminants, warm water can be used as the flush water to aid cleaning.

With the above options, whatever the application or parameter being measured, Process Instruments will be able to provide a monitoring system that will not only be accurate, precise and long lasting but that will also remain free from fouling and save the operator both time and money.

| Document | Type | Size |

|---|---|---|

| PeroxiSense | Brochure | 655kB |

| Using Open Flow Cells with Membraned Sensors | Technical Note | 762kB |

| Probe Fouling | Technical Note | 459kB |

"The support from Pi and its partners is superb. They go above and beyond to ensure that, not only is their equipment perfect but that the process is working great too. Five Stars!"

Anthony Glitto

Equip Solutions - Illinois, USA